What is the ToolScout?

Choosing the right tool and getting accurate application data is critical to getting your part the shape you want it to be. Whether drills, milling cutters, turning tools or gauges - in ToolScout you will find the right tool and individual application data in 16 languages for every application.

More than 50,000 cutting tools from all manufacturers are now stored. For the tool search and cutting data calculation, a comprehensive material database - with information on hardness and specific cutting force, among other things - is also taken into account.

How does the ToolScout work?

After selecting the process and the material, you specify your machining task. The resulting list of hits offers you objective comparison options. For example, you can select several tools from this list for a cutting data comparison. Among other things, parameters such as cutting speed, feed and machining time are compared. You can also display a profitability analysis of the selected hits. This shows the comparison of tool and machine costs as well as the material removal rate graphically. As in many other areas of the ToolScout, you can download both the cutting data comparison and the profitability analysis as a PDF.

Modules and functions

Reliable tool search

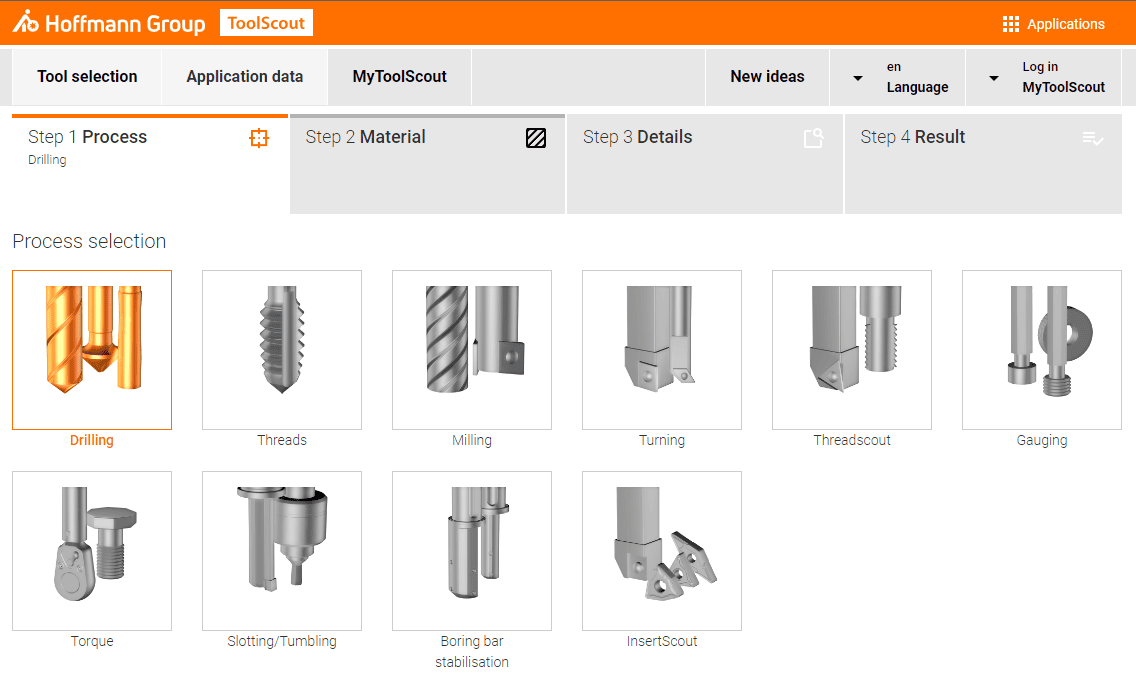

The ToolScout offers a reliable tool search - in four simple steps:

- Choice of procedure

- Determination of the material to be processed

- Specification of the processing task

- Display of the result list

Filter and sorting options

Extensive filtering and sorting options in the results list - for example by cooling/lubrication or shank - then quickly lead you to the desired tool. Have you found what you are looking for? Then benefit from the seamless process chain and order directly in the Hoffmann eShop. Alternatively, you can download the hit list as a PDF or save it in MyToolScout.

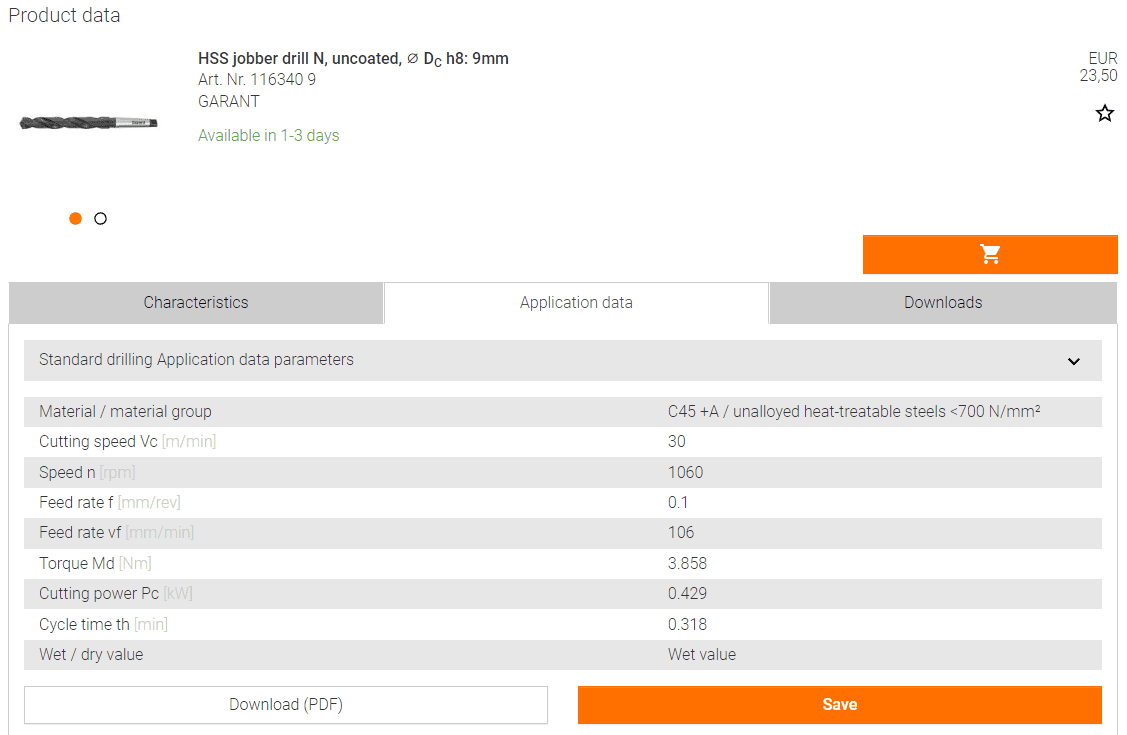

Provision of application data

In the application data area, after entering an article number and a simple selection of materials, you will receive planning-safe cutting data as well as extensive tool information and CAD data. This gives you all the data you need to optimally plan your manufacturing process - including feed rate and speed as well as the power and torque required to set your machine tool correctly. The appropriate gauge for torque wrenches is calculated on the basis of an extensive library of plug-in tools.

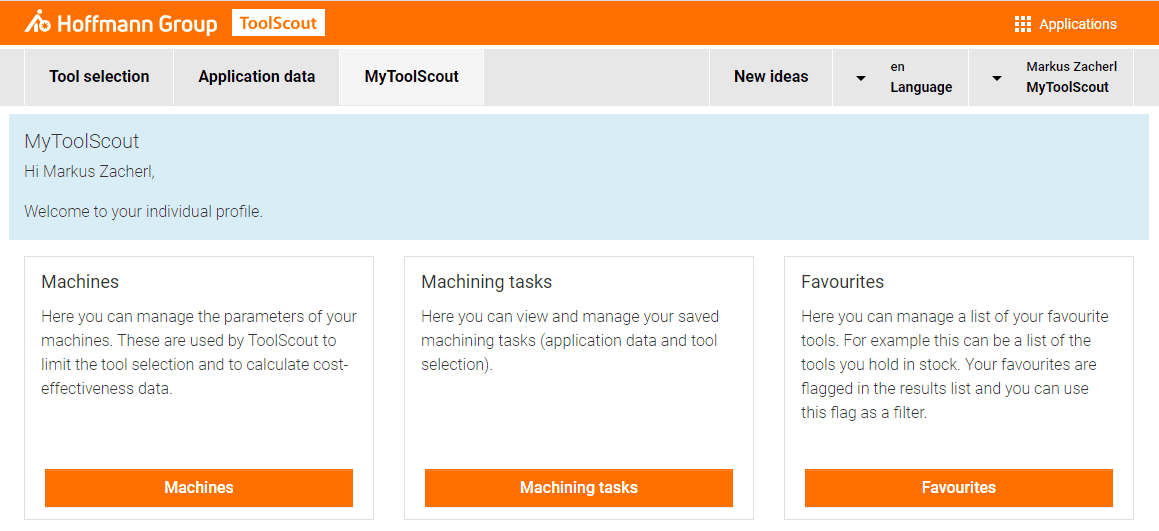

Configuration of the personal working environment

Would you like to make it as easy as possible for your next tool search? By registering on the digital service platform of the Hoffmann Group, you can configure and save your personal work environment: from individual machine data to machining tasks and tool favorites.

Machinery

In this area you can manage parameters of your machine tool. These are used by ToolScout to narrow the tool search, calculate profitability data and display machine diagrams.

Editing tasks

Here you can view and manage your saved machining tasks (tool searches and application data).

Get started with digital manufacturing now!

Get to know our digital product range! Our process consultants will guide you through our software range in approx. 30 minutes without obligation and work out the potentials for your company.

- Overview of the entire software range

- Tailor-made advice on your priorities

- Individual recommendations for your company