What is up2parts?

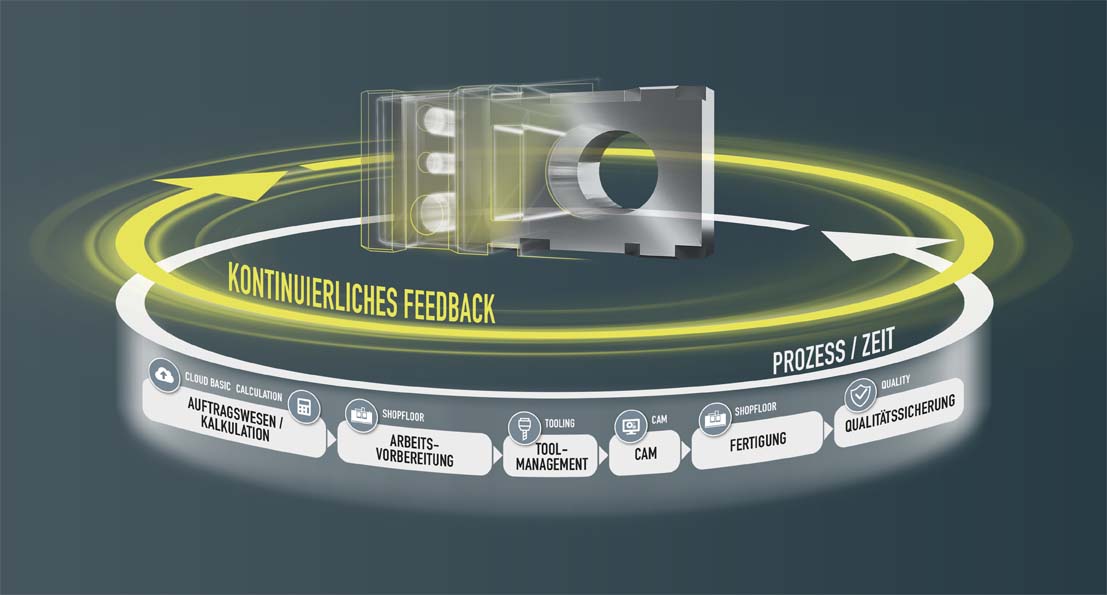

Do you want to put an end to tedious paperwork and endless spreadsheets for your work plan creation and price calculation? Reduce the processing time for a quotation to a few minutes? With up2parts calculation, you can automate work preparation and create concrete schedules and component cost estimates up to 80% faster. This lets you create four times as many quotes in the same time and increase your success rate. Your individual artificial intelligence keeps an eye on all parameters, such as utilization and optimum throughput of your production, the complexity of the component and current material prices.

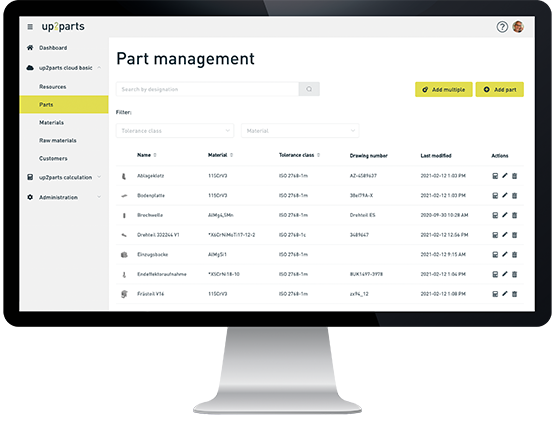

Our geometric similarity search brings speed into your component management. Find identical or similar components automatically and in seconds. Also manage and maintain your master data, such as items, drawings, 3D models, raw materials, customers, machines and workstations: centrally and in unlimited quantities. You always maintain the overview with up2parts cloud basic.

Modules and functions

up2parts cloud basic

- Find similar components in seconds

- Access your data anytime & anywhere

- Continous learning of your manufacturing processes

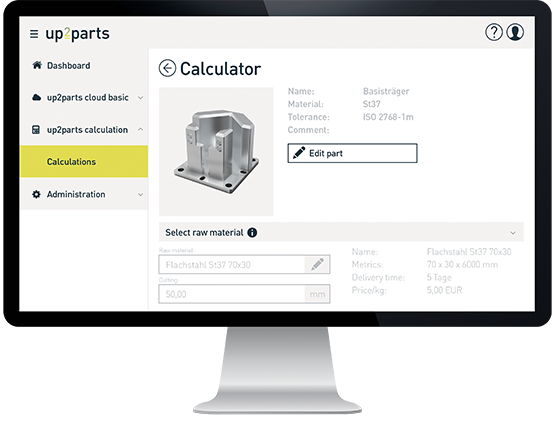

up2parts calculation

- Automatic work schedule creation

- Mailable quotes in just 3 steps

- Create more quotes with fewer resources

Highest data securit

Your data belongs exclusively to you. Neither up2parts GmbH nor our partner companies or other customers get insight into your stored company, machine and component information. We guarantee it. Our cloud is subject to the highest security standards.

FAQ

Who is behind up2parts?

up2parts GmbH is a software company specialist in the development of efficiency-enhancing solutions for the digitalisation of production processes. Our team consists of 80 software developers, including 15 Al experts/data scientists (as of August 2021). up2parts GmbH was founded in 2019 in Weiden in the Upper Palatinate, as the former software department of the modern contract manufacturer BAM GmbH with 150 employees. The experience and daily work of today·s sister company BAM are used by up2parts GmbH as a basis for the development of innovative software solutions.

For which machining processes is up2parts suitable?

Basically, the variety of manufacturing processes and materials that can be integrated is unlimited. Automatie calculations can be created according to the current state of development by means of a company-specific artificial intelligence (Al) for the processes milling, turning and sheet metal working or Laser cutting. The development of up2parts is ongoing.

ls there an ERP connection?

We provide our customers with an open API (standard interface). This means that our up2parts products can be integrated into your digital systems, such as ERP or CRM. Simply contact us for this. In addition, you have the possibility to carry out .csv imports & exports.

How secure is my data?

We do not allow for any compromises when it comes to the security of your data. This is why we work exclusively in accordance with the highest standards and host the data in Microsoft Azure Europe (i.e. your data is never hosted on local servers). We rely on state-of-the-art cloud technologies with multiple layers of encryption, for example, through permanent SSL & TSL encryption during data transfer. All 3D models, drawings, customer databases and other data are located in server-side encrypted data storage in accordance with the FIPS 140-2 standard (AES 256-bit). It is likely that your data has never been as secure as it is in this advanced cloud.

I don´t have a 3D model, am I able to use up2parts calculation as well?

No 3D model of the component available? No problem. Even with 2D drawings you can use the immense advantages of up2parts calculation. You only need to create the work plan manually with a few clicks based on your individual data. The software then takes over the price calculation fully automatically.

Does the AI also learn work steps? (e.g. after milling still hardening etc.)

The company-specific AI learns your work steps by creating calculations and offers them in a subsequent calculation. For example, if you always harden certain materials after they have been milled, your company-specific AI learns this and offers you the hardening step for suitable parts. It is important that you create a resource for the work steps to be learned. This is the only way the AI can learn from your work plans.

What do I need to calculation automatically?

In up2parts cloud basic, resources (machines), materials and raw materials must be created for a successful automatic calculation. It is important that suitable raw materials are available. You also need a step file of a turned or milled part. However, if you have not created any resources in up2parts cloud basic, up2parts calculation will suggest a suitable process for the part and inform you that you have not created any suitable resources. A manual calculation can also be done without a step file. You can create a work plan manually at any time.

What is the up2parts AI?

The up2parts AI, which works behind up2parts calculation, consists of a core intelligence and a shell. The core intelligence describes the company-independent WHAT on the component and is used to analyse general information, such as component size: 50x20x50 mm, 10x5 mm groove at position X/Y/Z. The shell of the intelligence describes the company-specific HOW on the component and is used by training. The intelligence envelope describes the company-specific HOW on the component and becomes more intelligent by teaching you. It serves to preserve your expertise, which is a major advantage of up2parts calculation. The information supplier for core and shell is the specially developed feature recognition.

How does the up2parts AI gets trained?

The up2parts AI learns from your calculations. We like to compare the learning process of artificial intelligence with an apprentice in the 2nd year of apprenticeship, which we provide you with up2parts calculation. This apprentice can provide you with valid calculation results, but he still needs some support to apply your company-specific knowledge. So you teach your apprentice the HOW and thus train the shell of your AI. It is important that you adjust the automatically calculated times (running time, set-up time) to your company-specific times so that the AI (your up2parts apprentice) can learn from your corrected times. Your adjusted routings are also used as learning material for your company-specific AI. In doing so, it learns from every calculation stored in up2parts (recalculations). Through continuous learning you increase the calculation accuracy. The learning speed depends on the variety of parts and production. Due to the high computing power required for this, we always train your company-specific AI at the weekend.

How fast does the AI learn?

The artificial intelligence learns from 10 stored calculations. Due to the high computing power required for this, the up2arts AI is retrained at the weekend. As already described in "how does the up2parts AI learn", you can compare our AI with an apprentice in the 2nd year of his apprenticeship, who can create quite acceptable calculations, but is still dependent on your company-specific knowledge. If you always let this apprentice calculate the same simple cube, he will master it perfectly in no time and provide you with a very good calculation result. However, if you have a very large variety of parts and production, your apprentice will need a little more time to build up new and extensive company-specific knowledge. In the same way, you need to look at the learning time of your company-specific AI. The learning speed that the up2parts AI needs to learn from you depends strongly on your component and production diversity.

Get started with digital manufacturing now!

Get to know our digital product range! Our process consultants will guide you through our software range in approx. 30 minutes without obligation and work out the potentials for your company.

- Overview of the entire software range

- Tailor-made advice on your priorities

- Individual recommendations for your company