What is oee.ai Manufacturing Intelligence?

Are you responsible for expensive machinery and have the task of getting as much out of the investment as possible? Then we are pleased that you have found us here. With oee.ai we help you to determine the productivity of your production in real time, to identify productivity potential and to motivate your employees for optimization. By using oee.ai you get the maximum out of your production - together with your team. In the following sections we give you an overview of oee.ai. Production optimization is complex, the environment is dynamic, technology is developing rapidly. This description only gives a small overview. So let us also talk about your specific requirements. Because no production is like the other.

Modules and functions

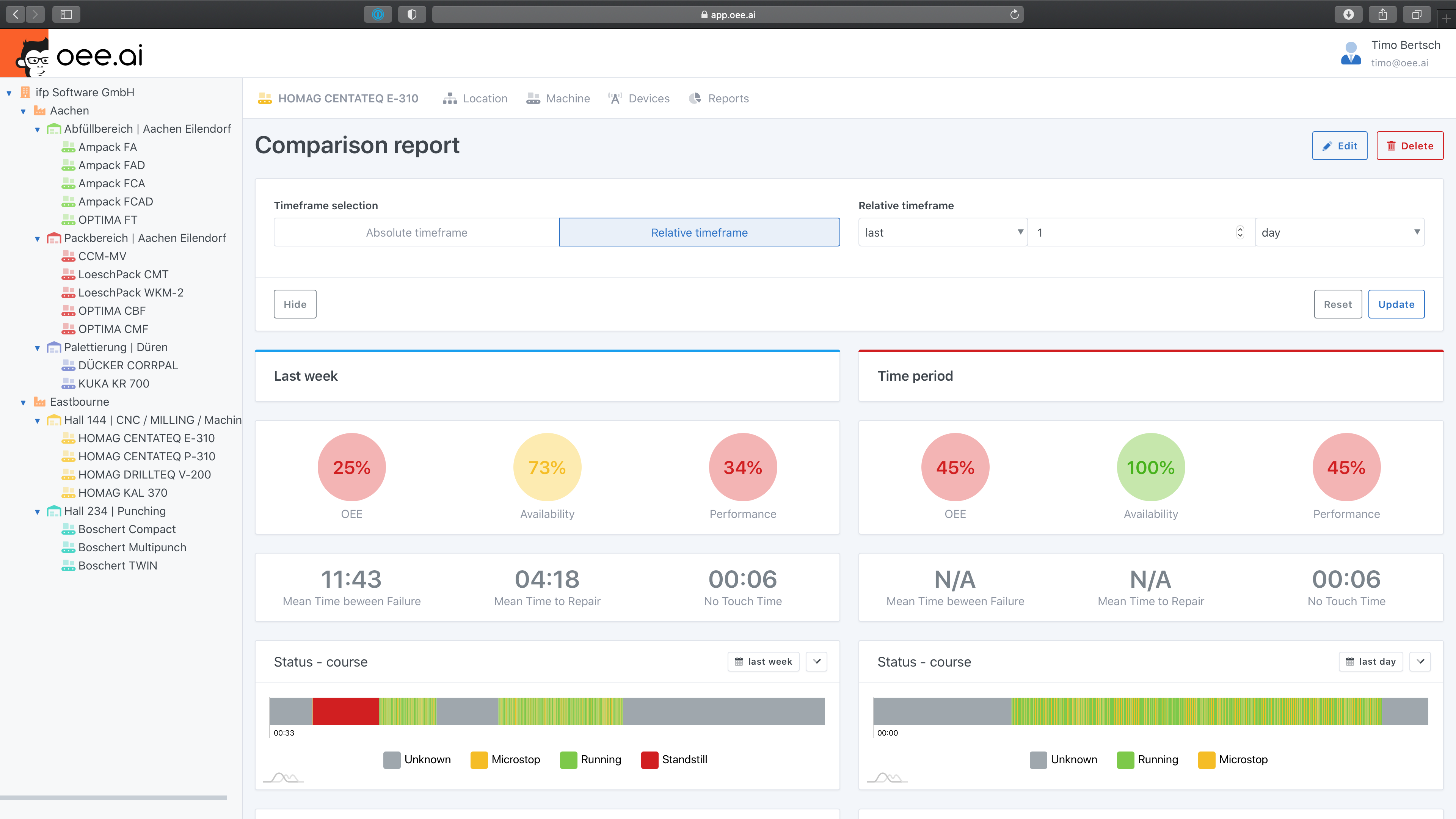

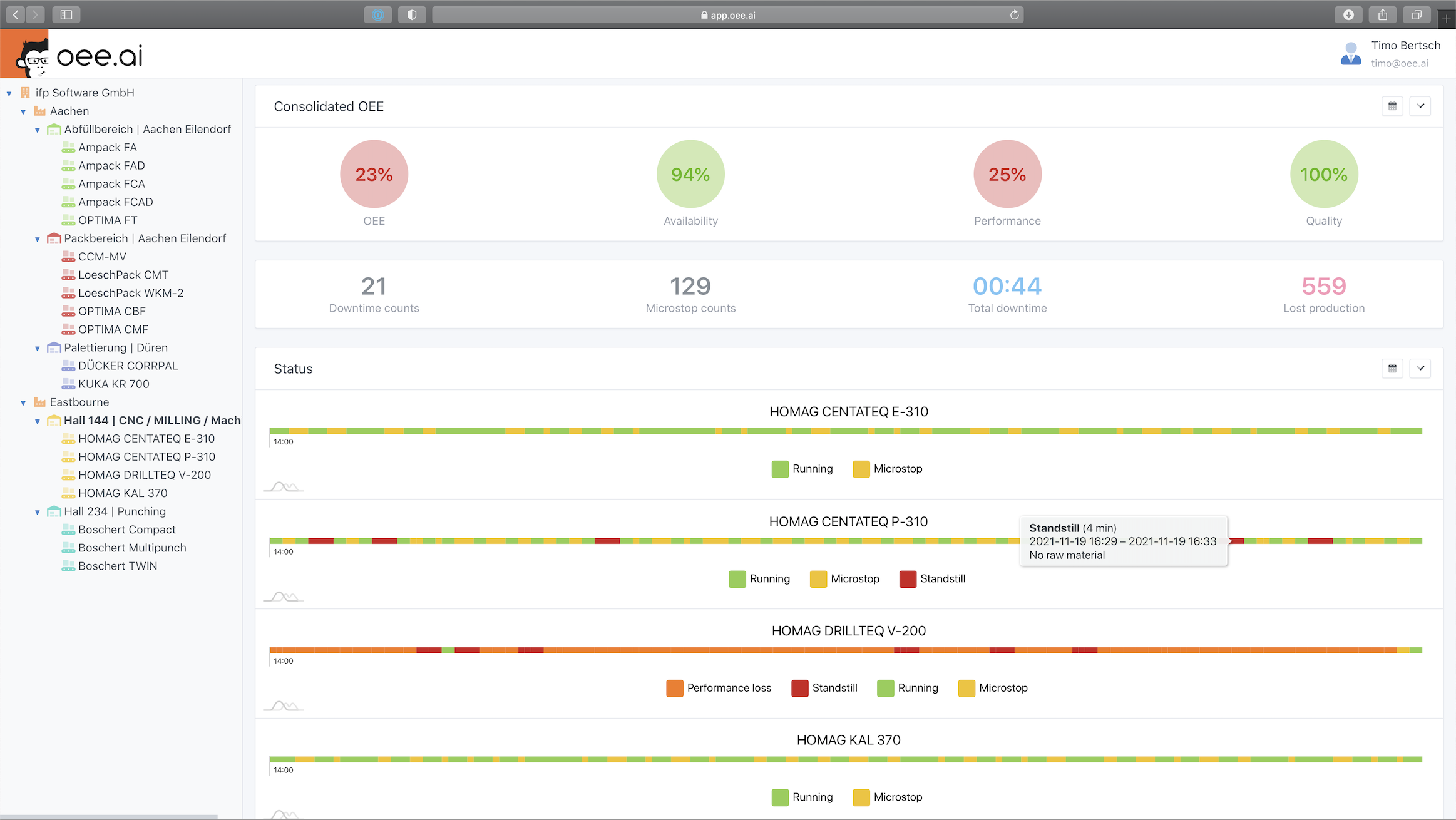

Individual reports adapted to your needs

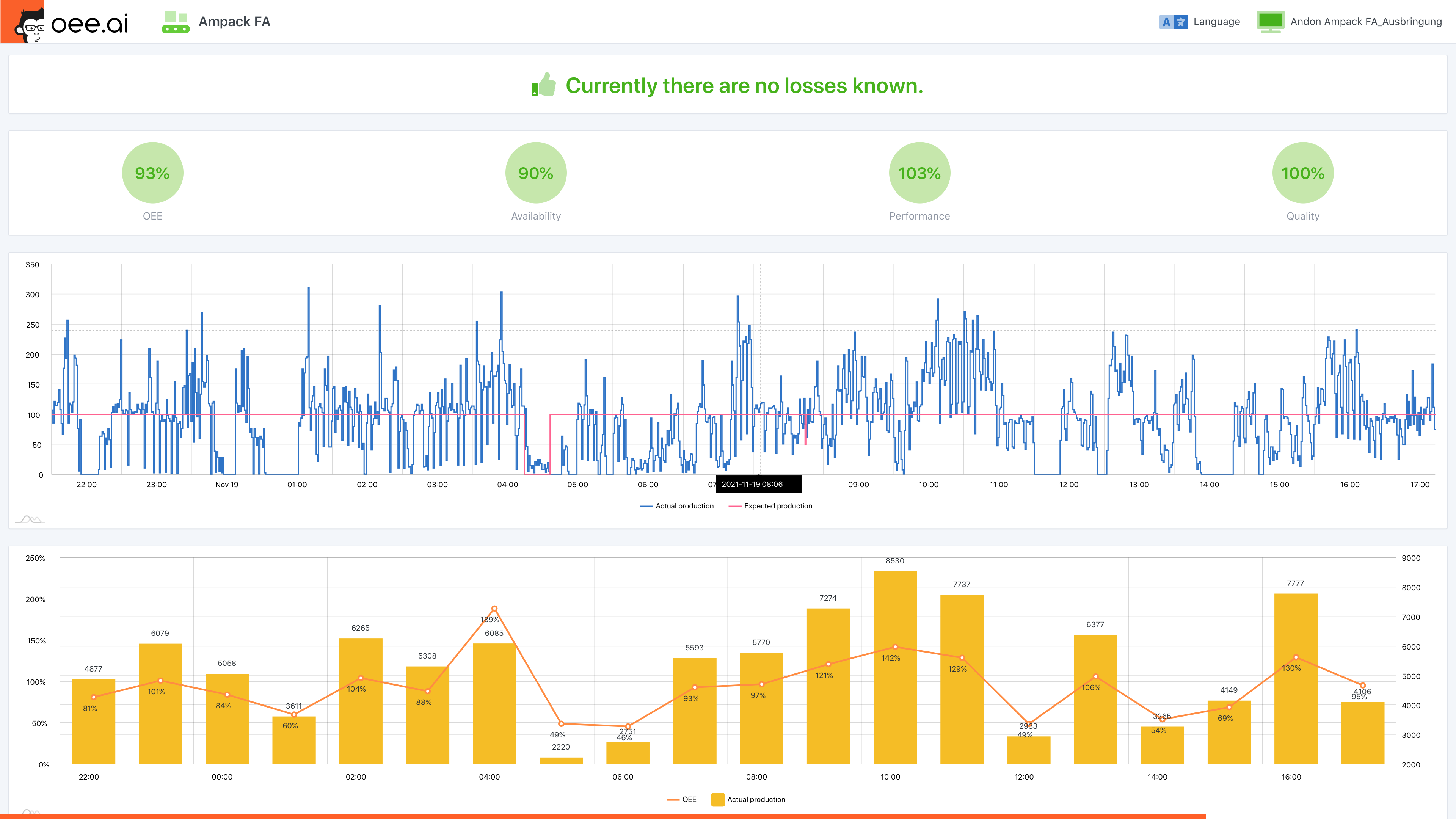

Up-to-date information at the push of a button

Make selected evaluations available on the store floor

One step ahead thanks to AI analyses and social manufacturing

Connection of heterogeneous plants from one source

Uncomplicated extensibility thanks to our SaaS model

FAQ

How does the data transfer to oee.ai work?

Can I customize the oee.ai system according to my needs?

Does oee.ai also work with small batch sizes?

Where can I learn more about OEE and oee.ai?

Get started with digital manufacturing now!

Get to know our digital product range! Our process consultants will guide you through our software range in approx. 30 minutes without obligation and work out the potentials for your company.

- Overview of the entire software range

- Tailor-made advice on your priorities

- Individual recommendations for your company