Using the tool management Connected Manufacturing: Paperless production reduces non-productive times by 30 percent

Mühlhoff Umformtechnik GmbH from Uedem am Niederrhein in Germany manufactures parts and components for the automotive sector. Since its founding in 1832, Mühlhoff has repeatedly adapted to changes in the market and demonstrated its innovative spirit. As one example of this, in 2020 the company opted for the Connected Manufacturing software from the Hoffmann Group to digitalise its order processing, data management and tool management workflows. The new tool management system enables tools and their condition to be tracked in real time.

700 tools under control

Michael Dückers, Project Manager for Toolmaking and Head of Machining Toolmaking at Mühlhoff, explains: “We use Connected Manufacturing for the production of individual components and small-scale series in toolmaking. With 700 tools, we mill 250 individual components on average for each tool mould and change the tool in the machines 2500 times. That equates to around 50,000 tool changes each year. That’s why digitalising our tool management system is hugely advantageous for us. We chose Connected Manufacturing because this software deals with tool and data management the best and offers an interface to the Tebis CAM system.”

Start repairs at the touch of a button

“For us, everything is now digital,” comments Dückers: “No paperwork, no Excel lists, whiteboards, program sheets or viewers, and instead shorter non-productive times and an overview of production in real time. We get twice the benefit when it comes to repair orders for tool moulds, as we’re now also managing them using Connected Manufacturing. Overall, we’ve reduced non-productive times by around 30 percent.” This saves money!

Noticeable improvements to processes

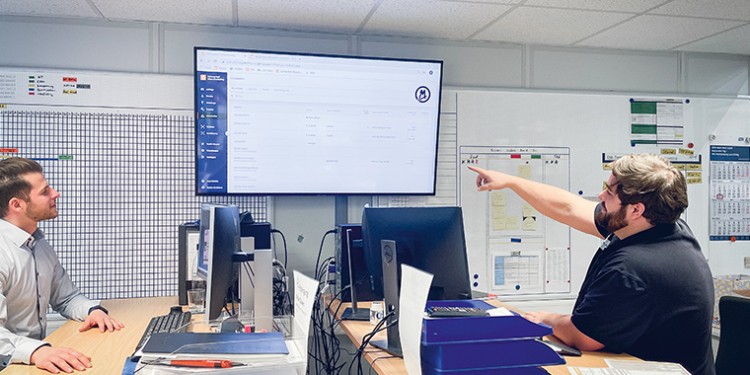

Mühlhoff also attributes the enormous time savings achieved with Connected Manufacturing to the extensive work done to optimise the processes. “We wanted to revamp our structures, so we looked very closely at our processes,” explains Dückers. Alexander Schmitz, Process Optimisation Specialist, is a qualified machinist and tool mechanic. He also worked for many years as a CAM programmer and measurement technician and knows machining workflows like the back of his hand. Schmitz comments: “The software simulates the main process. We looked at several software solutions and determined that Connected Manufacturing is the only one that lets us see what happens after the machine – i.e. where the tools are and what they look like. This is the crucial aspect. The software installation itself was very quick. “The first milling machine was connected after just two weeks; the IT department merely had to help with integrating the device into the company network and firewall. Thanks to the excellent cooperation with our IT department, we can solve a lot of issues ourselves as a company, and if there are serious problems the Hoffmann Group Support team is always ready to help,” explains Schmitz. In total, it took around four months for the process optimisation work to be completed and to connect the fourth milling machine.

Once the tool has been measured on the pre-setting device, an employee sends the measurement data to the Connected Manufacturing software by scanning the RFID chip.

The employees always have mobile access to the production data on their tablets.

Source of motivation for the team

From the outset, Connected Manufacturing was received very well by the employees. The younger staff were pleased that tablets are now being used in the Production department – after all, using modern technology makes work more enjoyable. The older staff also recognised the added value and quickly became familiar with the system. A total of fifteen employees now work with Connected Manufacturing. As result, they can now organise themselves and their work practically independently. Dückers adds that at Mühlhoff, the staff feel well equipped for the future: “For our staff, it’s important to see that we remain fit for the future. Implementing Connected Manufacturing is an important milestone on this journey, and it is being developed further by real industry specialists. If you want to get the most from it, you should also streamline the processes and assign a dedicated employee to this task for the first three months, at least temporarily.” Schmitz is also delighted, adding: “Plus we have the Hoffmann Group’s exceptional focus on service. We feel we’re in very good hands with Martin Hupke as the first point of contact at the Hoffmann Group. We receive an expert, personal service – that’s extremely important in the case of business-critical software like this.” Michael Dückers agrees: “We have never regretted our decision and can gladly recommend Connected Manufacturing.”