What is Spanflug Make?

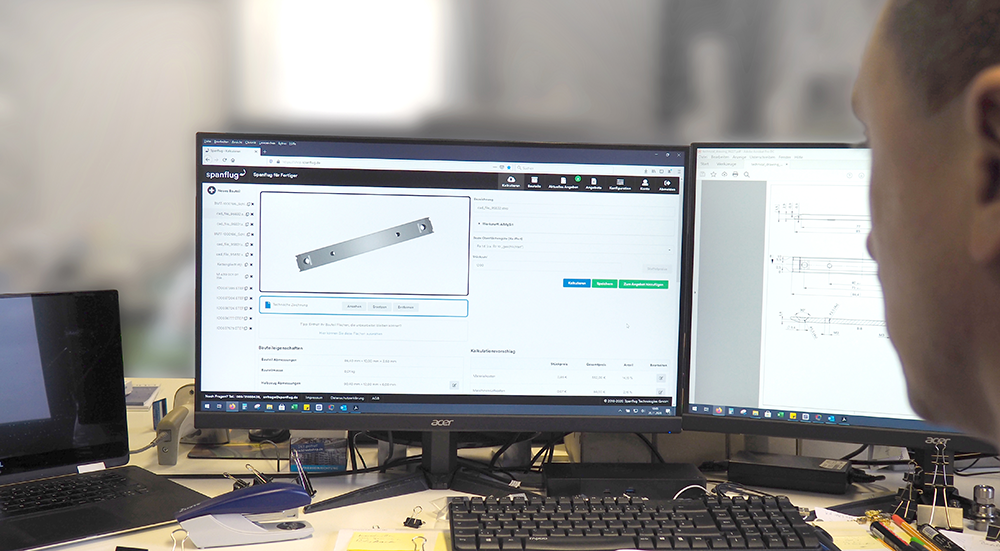

With Spanflug Make you can calculate the price for turned and milled parts with just a few mouse clicks. The automatic price calculation is based on CAD models. In addition to the CAD model, you can automatically evaluate other parameters (e.g. specific tolerances, fits and threads) from the technical drawing. A comprehensive semi-finished product database with more than 50 materials and a selection of over 20 post-treatments is available to you as standard. Spanflug Make is a software-as-a-service solution. You can register within a minute and calculate prices for CNC parts immediately without further installation. Calculate 5 components per month free of charge. In addition, you can use Spanflug Make as a monthly or yearly subscription for unlimited calculations without high initial investment and maintenance costs. The total costs are transparent and easy to plan. Spanflug Make is a cloud-based solution that you can easily access via your browser. You do not need your own hardware and do not have to carry out any installation.

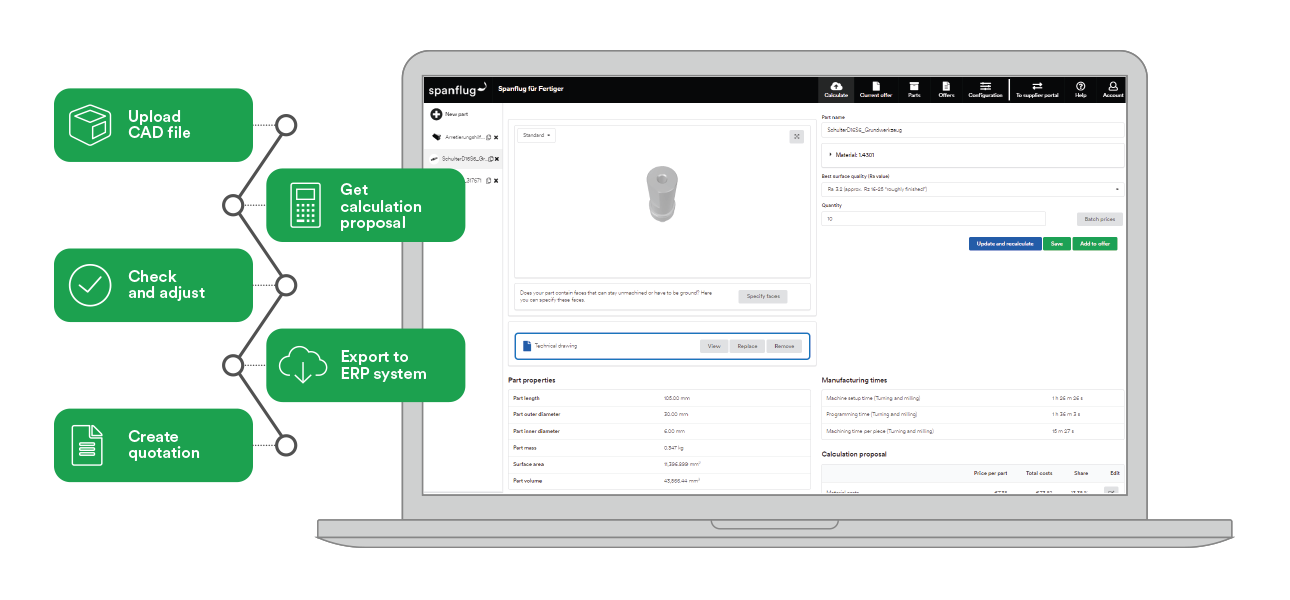

How does Spanflug Make work?

Spanflug Make can be used immediately without configuration. In order to achieve a result that is better tailored to your business, you can optimize the calculation in just a few steps. You have the option of storing your machine tools with the corresponding hourly rates. In addition to the machine park, you can adjust the following calculation settings for your company: cutting values, material costs, set-up costs, margin and overhead costs. We would be happy to support you with the configuration. On request, we also carry out individually tailored training courses on site or remotely.

Modules and functions

Automatic component analysis

We analyze the geometry and manufacturability of the components using the CAD model (STEP). All other relevant details such as fits, threads and tolerances are automatically read from the technical drawing (PDF). Manual entries are not necessary.

Individual manufacturing process

Our price calculation is closely based on the actual manufacturing process. Using the calculation settings and the machinery, you can map the conditions in your company with just a few clicks and optimize the calculation.

Leading platform technology

Our technology was developed for the Spanflug platform and is an international leader in the field of CNC machining. As a user of Spanflug Make, you will continue to benefit from all improvements in the future and secure important competitive advantages for yourself in the long term.

Proven pricing algorithm

Using our pricing algorithm, you can create a calculation proposal in just one minute. The algorithm is based on our extensive expertise in the field of CNC manufacturing and has been optimized using thousands of components.

High protection standard for sensitive data

Technical data such as CAD models and construction drawings often contain critical know-how and are subject to particularly high confidentiality requirements. In order to meet these requirements, we guarantee a particularly high standard of information protection.

The processing of your technical data takes place exclusively on servers in Germany that are managed by us and certified according to ISO 27001. We rely on industry standard best practices in software development. The connection to our servers is encrypted via TLS.

In principle, our employees only have access to component data after your approval, e.g. B. for support requests. The data can be deleted at any time after processing. We would be happy to conclude a non-disclosure agreement with you. Personal data is processed in accordance with the statutory provisions of the Federal Data Protection Act (BDSG) and the European General Data Protection Regulation (GDPR).

FAQ

Is it possible to save calculations in order to process follow-up requests more quickly?

Yes, you can archive parts, calculations and quotations with Spanflug Make and recall for subsequent requests.

Can the calculation be customized to my operation?

You have the possibility to set up your CNC machines. However, you can also use the software without the individual machines based on preconfigured machine tools. In addition to the machine tools, cutting values, material costs, setup costs, margin and overhead costs can be adjusted.

Can quotations be managed and exported with the software?

Yes, you can add the automatically calculated quote prices to a quotation and export it as a csv file. You can then import this csv file into your ERP system for further processing.

Why should I adjust the calculation settings?

Spanflug Make makes quoting of turning and milling parts as easy and fast as possible. Via the settings you can optimize the calculation to your operation and your price level. Individual parts can then be calculated automatically without adjusting the configuration every time.

What happens to my data?

Your data will be used exclusively for your calculations. Our employees receive access exclusively according to the need-to-know principle to be able to process your support requests. Your data can be deleted at any time.

What are the technical requirements for using the software?

Spanflug Make is a cloud-based software-as-a-service solution that runs in the web browser. All you need is a PC with Internet access and a web browser. No installation of the software or special hardware is required.

Get started with digital manufacturing now!

Get to know our digital product range! Our process consultants will guide you through our software range in approx. 30 minutes without obligation and work out the potentials for your company.